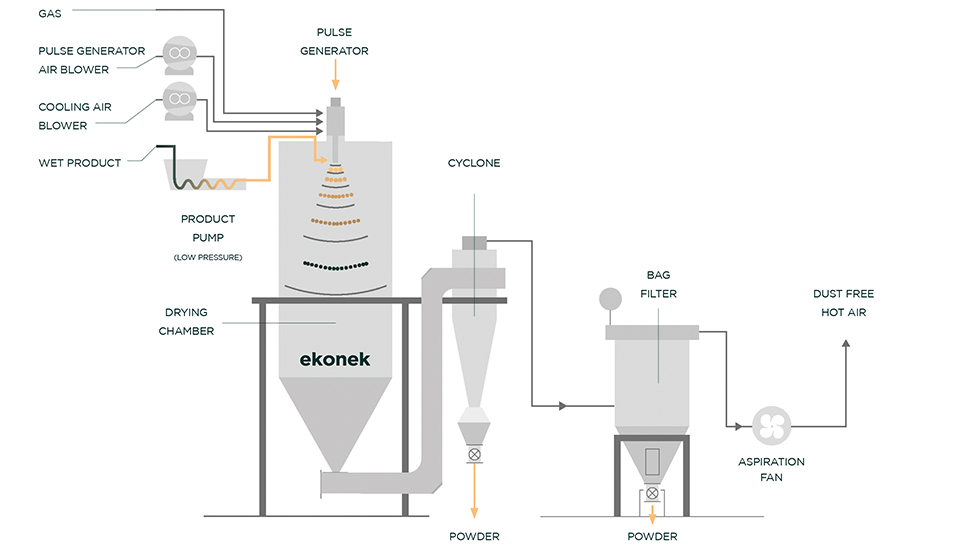

Pulse Spray Drying (PSD)

Transforms liquids and pastes into powder instantly while preserving the nutritional value of the product with huge energy savings.

Key Benefits

Atomization of products that cannot be processed in conventional dryers

It can atomize products with higher viscosity, higher concentration, or products containing fibers/solids up to phew mm.

Lower running cost

Energy efficiency: 20-30% lower running cost than spray dryers.

High final product quality

Keeps the nutritional value of the products.

Lower manteinance costs

No nozzles or discs that have to be frequently changed.

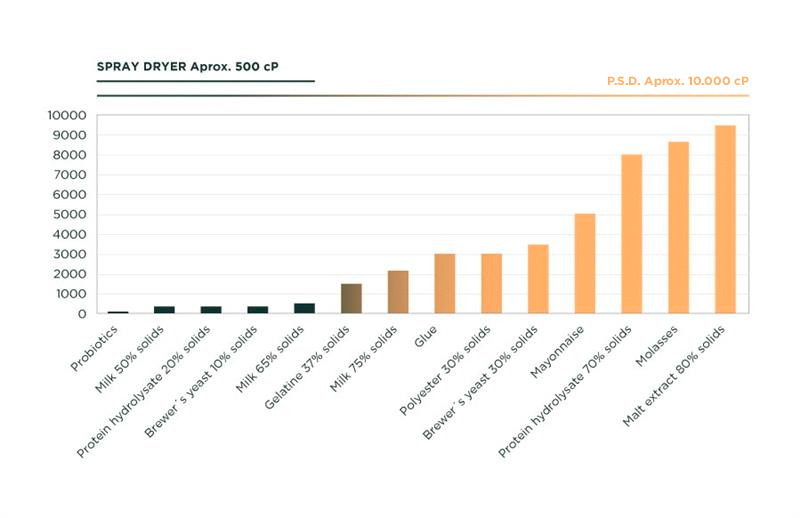

HIGH DRY MATTER AND VISCOSITY PASTES DRYING

The next graph shows the wide potential of new products that can be atomized with PSD : we can handle 10+ times higher viscosity, or more.

MODEL FEATURES PSD

| Model | Thermal Power | Evaporation |

|---|---|---|

| PSD - 70 | 70 kW | 70 kg/h water |

| PSD - 350 | 350 kW | 350 kg/h water |

| PSD - 700 | 700 kW | 700 kg/h water |

| PSD - 1000 | 1000 kW | 1000 kg/h water |

| PSD - 2000 | 2000 kW | 2000 kg/h water |

| PSD - 3000 | 3000 kW | 3000 kg/h water |

Some applications:

Industry applications

Interested in learning more about Ekonek ?