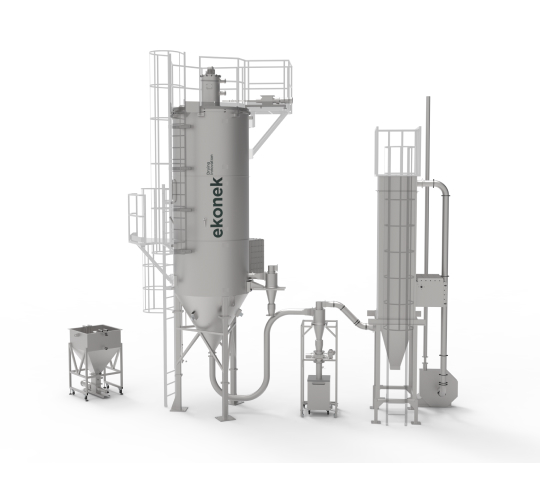

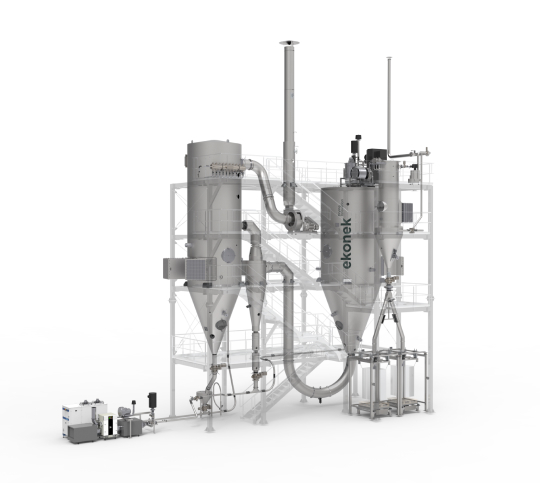

Pulse Spray Drying (PSD)

Instant tranformation of liquids and pastes into powders, processsing high-quality products with benefits that make a difference.

Benefits

Strong advantages over traditional drying systems.

Possibility for drying liquids and pastes with high viscosity and high concentration, impossible for other drying technologies.

High final product quality.

Energy consumption typically 20-30% lower than conventional technologies.

Important reduction of microbiological contamination.

Compact design. Smaller equipment size than similar capacity spray dryers.

Quick, easy and economic retrofits of existing spray drying plants increasing evaporation capacity with low investment.

Reduced maintenance works and costs. Robust design. No use of rotary atomizers nor high pressure pump + nozzles.

Easy to operate.

Testing facilities

Available pilot plants designed to develop, test and validate our client's processes, allowing to determine the optimal solution for each project.

Type of projects

GREENFIELD PROJECTS

We design and implement complete drying solutions from scratch, developing fully customized facilities tailored to our clients' needs.

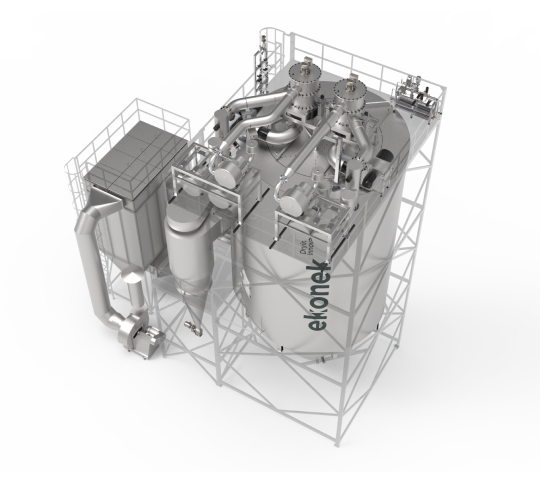

RETROFIT PROJECTS

We integrate our technology into existing spray dryers, optimizing processes and increasing effiency and capacity without the need for a full-scale rebuild.

Interested in learning more about Ekonek ?